CAMWorks Crack is an innovative computer-aided manufacturing software developed by Geometric Technologies, which is revolutionizing the manufacturing industry. With its user-friendly interface and powerful features, CAMWorks provides manufacturers with a comprehensive solution to streamline their production processes and improve overall efficiency. What sets CAMWorks apart from other similar software is its intelligent automation capabilities.

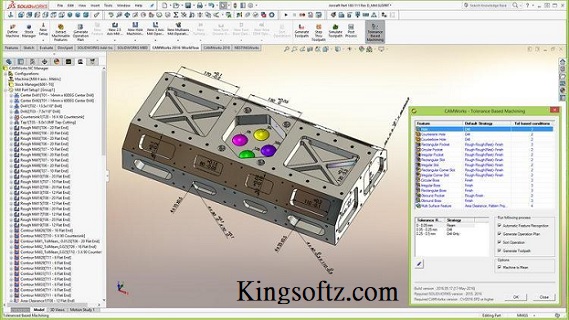

One of the key strengths of CAMWorks lies in its ability to seamlessly integrate with popular 3D CAD platforms such as SOLIDWORKS. This integration allows for an effortless transfer of design data from the CAD model to the CAM system, eliminating errors and reducing time-consuming manual programming tasks. By analyzing the geometric features of a design, CAMWorks can automatically generate toolpaths, select appropriate cutting tools, and optimize machining strategies – all while considering factors such as material properties and machine limitations.

CAMWorks 2023 Crack + License Code Full Version

CAMWorks Serial Key 2023 incorporates advanced simulation tools that enable manufacturers to visualize the machining process before actual production begins. This aids in identifying potential issues or collisions between components, saving both time and resources. The software also includes comprehensive reporting features that provide detailed information about cycle times, tool wear, and material usage – allowing for accurate cost estimation and efficient resource planning. This not only saves time but also prevents costly mistakes on actual machine tools.

CAMWorks is not just another run-of-the-mill computer-aided manufacturing software – it’s a forward-thinking solution that empowers manufacturers with enhanced productivity and unmatched precision. It’s truly remarkable how this technology has transformed traditional machining processes into efficient automated workflows while maintaining utmost accuracy every step of the way. CAMWorks is a computer-aided manufacturing (CAM) software solution primarily used for creating toolpaths and generating CNC (Computer Numerical Control) programs for machining parts and components.

CAMWorks Crack 2023 is a CAD/CAM software that combines the power of 3D modeling with automated machining capabilities. With its intuitive interface and robust features, CAMWorks enables manufacturers to streamline their production processes and increase efficiency. What sets CAMWorks apart from other CAM systems is its unique Tolerance Based Machining (TBM) capability. Instead of relying on traditional dimensions, TBM uses tolerance information directly from the 3D model to automatically generate tool paths, ensuring high precision and reducing manual input errors. We also updated the AmoyShare AnyErase Pro Crack.

This allows designers to create their models in familiar CAD environments while benefitting from the intelligent machining functionality offered by CAMWorks. It streamlines the workflow by automating the transfer of design data and eliminating the need for file conversion or importing/exporting operations. Simulating tool paths and material removal, allows manufacturers to identify potential issues upfront, such as collisions or excessive stock removal. Another standout feature of CAMWorks is its ability to integrate seamlessly with popular CAD systems like SOLIDWORKS.

CAMWorks offers versatile simulation capabilities that help users visualize how their designs will behave during machining. Overall, CAMWorks empowers manufacturers with an all-encompassing solution for efficient 3D modeling and automated machining. Its integration with popular CAD systems coupled with TBM capability makes it a go-to choice for businesses looking to optimize their production processes and ensure high-quality output without compromising on speed or accuracy.

Key Features of CAMWorks:

- Feature-Based Machining (FBM): CAMWorks uses a feature-based approach to programming CNC machines, which means it recognizes and programs features like holes, pockets, and slots automatically, saving time and reducing manual input errors.

- Automatic Toolpath Generation: CAMWorks can automatically generate toolpaths for 2.5-axis to multi-axis milling, turning, mill-turn, and wire EDM machines. This simplifies the programming process.

- Integrated with SOLIDWORKS: CAMWorks is often integrated into SOLIDWORKS, a popular 3D CAD software. This tight integration allows for seamless data transfer between design and manufacturing, reducing the chances of errors.

- Knowledge-Based Machining: CAMWorks incorporates a knowledge base of machining rules and best practices. This helps in optimizing toolpath generation and ensuring consistency in machining strategies.

- Simulation and Verification: It provides simulation and verification tools to visualize the machining process and detect any issues or collisions before sending the program to the CNC machine.

- Post-Processor Customization: CAMWorks allows users to create or modify post-processors to match specific CNC machine requirements, ensuring compatibility with a wide range of machines.

- Machine-Neutral Programming: It supports machine-neutral programming, meaning you can create CNC programs for different machine brands and models.

System Requirments:

- Operating System: Windows 7/8/8.1/10 or Vista

- Processor: 2GHz

- 2GB of RAM

- 200MB free backspace

- An Internet connection is required.

CAMWorks Keys:

- HGFQW-AESDX-FCGH-6TR3W-SEDF

- DFCG-VB876-TR3WS-EDFG7-6YTR

- XDCFV-B87Y-T3WQA-SZXDF-CGVHB

- UHGF4-3WQASZ-DXCFG-VHB87-6YTRD

CAMWorks Keygen

- XCV7-6TR32-QAWSD-XFCGH-YTFGH

- DFCGV-B87YT-WASZD-XFCGV-HYTFD

CAMWorks Serial Key

- YTGF4-3WSDXF-CGVH7-6YTRD-WESD

- FCGV-B7YTR-34WASD-XFCGV-HBJ8Y

CAMWorks Pros & Cons

Pros of CAMWorks:

- CAMWorks provides an easy-to-use interface, making it user-friendly and suitable for beginners.

- It offers quick and efficient toolpath generation, increasing productivity and saving time.

- The software integrates seamlessly with SOLIDWORKS, allowing for direct communication between design and manufacturing teams.

- CAMWorks provides advanced simulation capabilities, helping to identify potential issues before actual production.

- It supports a wide range of CNC machines and controllers, ensuring compatibility with various manufacturing setups.

Cons of CAMWorks:

- The software can be expensive compared to other CAM solutions in the market.

- Certain advanced features may require additional training or expertise to fully utilize their capabilities.

- The system requirements for running CAMWorks can be demanding, requiring powerful hardware configurations.

- The software may not have as extensive support or community resources compared to more popular CAM software options.

- Updates and bug fixes may not always be timely or frequent enough to address all user-reported issues promptly.

How to Use CAMWorks Crack Full Version:

Using CAMWorks typically involves the following steps:

- Import or Create CAD Geometry: Import the 3D CAD model of your part into CAMWorks or create one if not already available.

- Feature Recognition: CAMWorks automatically recognizes machining features like holes, pockets, and slots on the part.

- Define Machining Operations: Specify machining operations, such as roughing, finishing, and drilling, for each recognized feature.

- Generate Toolpaths: CAMWorks generates toolpaths for each machining operation based on your defined parameters and the recognized features.

- Simulation and Verification: Simulate the toolpaths to check for any issues, such as tool collisions or excess material, and make adjustments as needed.

- Post-Processing: Generate the CNC program code (G-code) for your specific CNC machine.

- Quality Control: Review the generated program and, if satisfied, transfer it to the CNC machine for machining the actual part.

FAQs about CAMWorks:

Is CAMWorks compatible with other CAD software besides SOLIDWORKS?

Yes, CAMWorks is compatible with other CAD software, including Solid Edge and Autodesk Inventor, although its integration with SOLIDWORKS is one of its most popular features.

Can I customize tool libraries in CAMWorks?

Yes, CAMWorks allows you to customize tool libraries with specific tooling information, such as tool dimensions, speeds, and feeds.

Does CAMWorks support multi-axis machining?

Yes, CAMWorks supports multi-axis machining, including 3-axis, 4-axis, and 5-axis machining, allowing for complex part production.

Is CAMWorks suitable for programming CNC lathes and turning centers?

Yes, CAMWorks includes capabilities for programming CNC lathes and turning centers in addition to milling machines.

Can CAMWorks simulate real-time tool wear?

CAMWorks primarily focuses on toolpath simulation and collision detection. However, it doesn’t provide real-time tool wear simulation, which is typically handled by specialized tool monitoring systems integrated with CNC machines.

CAMWorks Video Tutorial

- First of all, uninstall the previous version by IOBIT Uninstaller Crack.

- Then download the file by using the given link or IDM Crack.

- Extract the file by using WINZIP Crack.

- Install the setup file as normal.

- Then open the crack folder and install that patch file.

- Now you have done. Enjoy it.

- Please visit our site for the Full Version of the Software.